Christmas tree inspection tips

Check packaging and labelling - Check overall appearance - Check ease of assembly - Check size and weight - Check stability - Check flame retardancy - Check strength - Check other

1. Packaging and label inspection

-Outer box

(1) Whether the dimensions of the outer carton are correct. (2) Whether the markings on the outer carton are correct. (3) Whether the signs and labels are correct.

Whether fragile labels, warning labels, etc. are placed in the corresponding positions of the packaging as required, whether there are corresponding logistics barcodes such as ITF14, I2 of 5, EAN128 and other barcode requirements, whether the barcode size and position meet customer requirements, so as to suit the scanning of logistics operations , whether the barcode scan is correct

(4) Whether the sealing of the outer box is H-type and whether there are iron nails. Is the net gross weight of the outer box correct.

Check the packaging method, the width of the sealing tape, whether the iron nails are protected, whether there is warping, and whether the gross net weight of the outer box matches the order and the shipping mark.

-color box

(1) Is the size of the color box correct?

Check with the order, whether it conforms to the actual product size, whether a reasonable sealing method is adopted, and whether there are packaging gaps that may cause damage to the packaging and products during transportation

(2) Whether the color picture on the color box is the same as the product, whether there is damage or wrinkles

The product information on the color box includes pictures, size, number of branches, components, etc. Whether it conforms to the actual product, the color box is part of the sales package, whether the appearance and printing are acceptable, and no damage, wrinkles, deformation, cracking, and overlapping printing are allowed. , ambiguity, etc.

(3) Whether the instructions on the color box, bar codes, etc. meet the order requirements

Whether the assembly and use instructions on the color box are in line with the actual situation, and whether the code system of the bar code is in line with the code system. Generally, products in the United States and Canada use UPC12 bar code, and other regions use EAN13 bar code. Whether the size of the bar code meets the requirements, and whether the number of the bar code conforms to the order, Whether the barcode can be scanned and whether the scan result matches the printed number

(4) Is the label on the color box correct?

Whether price labels, fragile labels, warning labels, etc. are placed in the corresponding positions of the packaging as required, and whether customers have corresponding requirements for the tearability of the labels, especially for holiday promotion products, promotion labels on products and packaging, Whether the price label meets the requirements. For the price label, whether the price unit adopts the currency unit of the destination country. For example, the goods from Ireland should not have the pound symbol, the euro area countries should use the euro label, and the United States should use the dollar label, etc.

2. Overall appearance inspection

(1) Overall: whether the number of layers of branches and the number of branches and leaves meet the requirements of the order; whether the specifications and colors of the leaves meet the requirements; whether the overall style meets the requirements; whether the tree circumference and tree height of each layer after the tree is assembled meet the requirements of the order; Don't be too crooked after being assembled.

(2) Tree feet (base): After the tree is opened, press down with your hands to see if the feet are strong enough; if the tree feet are made of plastic, you can take the stump to see if the iron pipe will wear the plastic through the bottom.

(3) Branches: whether the length and thickness of the leaves meet the requirements of the order; whether the color meets the requirements of the order; whether the length of each branch meets the requirements of the order; whether the number of branches is consistent with the order; whether the branches of the branches have wire outcrops .

(4) Iron pipe and iron wire: Whether the diameter, thickness and length of the iron pipe meet the order requirements; whether the diameter, thickness and length of the iron wire meet the order requirements; The iron pipe is exposed during the leaf process; whether the branches are tied to the iron pipe loose or fall off.

3. Check ease of assembly

- Check whether the components in the manual are complete (if the size of the components is described in the manual, it needs to be measured);

- Check whether the assembly steps in the manual are reasonable;

- Check whether the actual assembly is consistent with the instructions marked;

- Check if the assembly process is easy;

- Check whether the branches are easy to open (it should be assembled separately with the assistance of the factory, check whether the actual assembly steps are in accordance with the instructions, whether the difficulty level is suitable for ordinary consumers, if the assembly process requires tools, whether it is included with the product packaging, if not included, Whether the required tools are indicated on the manual)

4. Check the weight and dimensions

- Whether the weight of the product matches the sample, order and product details (electronic scale or scale, determined by accuracy and capacity)

- Check size: tree girth size (maximum width when branches are fully opened);

-Whether the tree height is consistent with the order and marking (usually the tool used is a steel tape measure);

- Whether the total number of branches is consistent with the order and label;

- Whether the thickness of the leaves is consistent with the order and the label (the measuring tool is generally a spiral micrometer or a thickness gauge, which needs to be accurate to 0.01mm)

5. Check stability

Place the assembled whole tree on an 8-degree slope (or the customer's special request), and rotate the whole tree to the most easily dumped position, and the product cannot be dumped. If the product has decorations, all decorations should be assembled as required and tested. (Before using the slope, you need to correct whether it is 8 degrees, you can use a protractor or trigonometric function to measure)

6. Check flame retardancy

Christmas trees and Christmas decorations generally have flame retardant requirements, that is, after the material making up the product is in contact with the fire source, when the fire source is removed, the fire source on the product should be extinguished immediately.

Inspection method: Take the corresponding parts of the tested product, ignite it with a lighter, quickly remove the ignition source of the lighter, and observe whether the flame on the product goes out immediately.

Before the test, the components of the tested sample should be tested separately in an environment away from flammable materials. For example, when testing the branches of a Christmas tree or decorations on the tree, they can be removed and tested to prevent the material from having no flame retardant properties. fire hazard

7. Check the strength

Christmas tree branches - need to withstand 2KG tension within 10S: Christmas branches and leaves - need to withstand 0.5KG tension within 10S; ornaments' lanyards - need to bear 2 times the weight of the product; decorations such as fruits, flowers, etc. - need to withstand 10S 0.5KG tensile force (using the measuring tool tensile force meter)

8. Other inspections

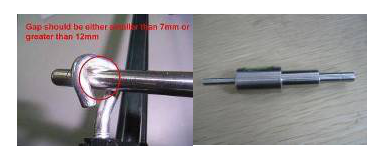

- Check safety gaps

Check the 7-12mm safety gap (there should not be a 7-12mm gap after the product is assembled, causing the risk of finger pinching)

- Check the wood moisture

The humidity requirement for Christmas decorations is 7-18% (using a wood moisture tester)

- Needle inspection (plush and textile decoration, etc.)

There should be no broken needles and metal objects in the plush and textile decoration, so as to prevent the impact on personal safety during use (use a needle detector or metal detector, and test the effectiveness with a standard module before use)

- Box drop test (ISTA)

If the product is found to have CRITICAL problems or lose its use function or the outer box is damaged after testing, it should be rejected; if only packaging wrinkles or minor appearance defects are found after testing, which does not affect sales, the actual situation will be noted on the report. To be determined by the customer; accepted if there are no problems.